Rather then spend many hours sanding and grinding I opted to take them to get blasted.

They used plastic media to "sand blast" the fenders..

and long nose parts. They did a great job too.

I have a little repair to do..

but not bad for fenders that were outside for 20 years.

Before digging into the Porsche body work I wanted to practice on an extra fender.

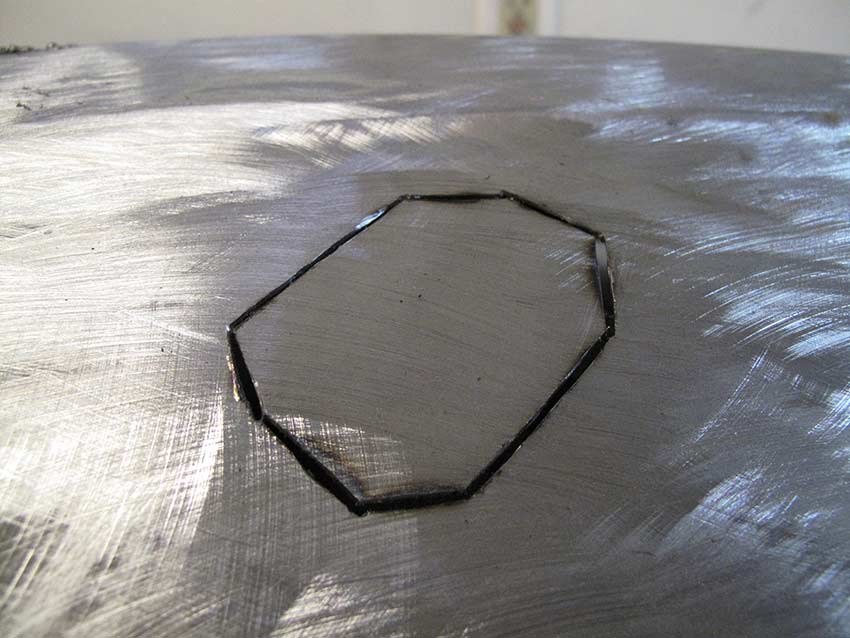

So I cut out a piece to weld back in.

A few weld tacks one of which blew through.

Spacing out the welds and letting it cool I managed to weld this back in. I did this a few times.

I started on the rust near the bottom of the left fender.

Outlined all the rust area to cut out.

After cutting out the outside piece there is rot on the inside as well. Of course.

Using the cut out piece as a template I cut the replacement from the donor fender.

Tacking it in. Using a heat sink and to spread out the heat.

Spreading out the welds its almost in. Have a few more tacks to do.

After a bit more tacks I ground it down with my die grinder.

Found a couple small holes by the gas filler.

Plugged the hole up

And the fender fits back in. Jesus the rocker panel needs work.

Onto the right fender.

Rust on the other side too.

Cutting away, nice bit of rust.

Now to cut a few patches to fit in there.

And its done

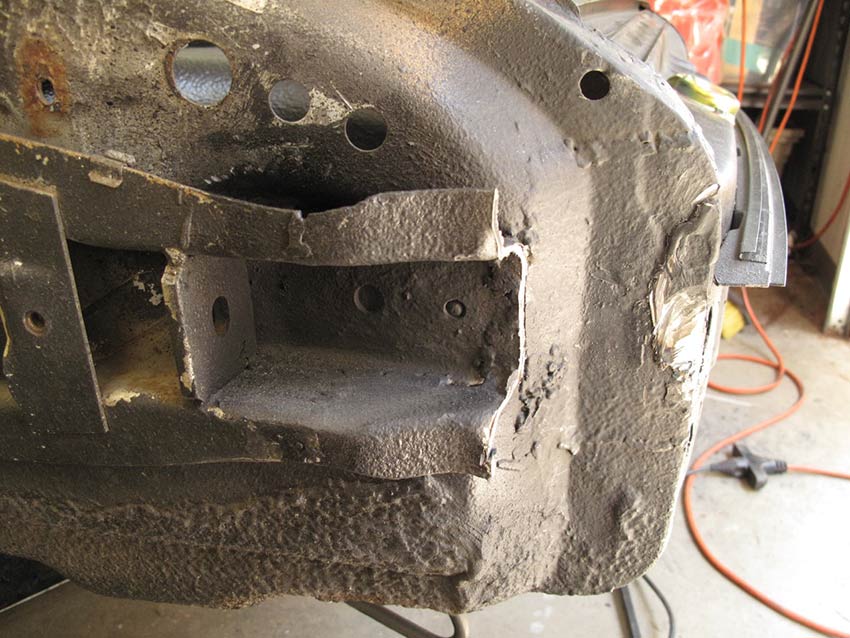

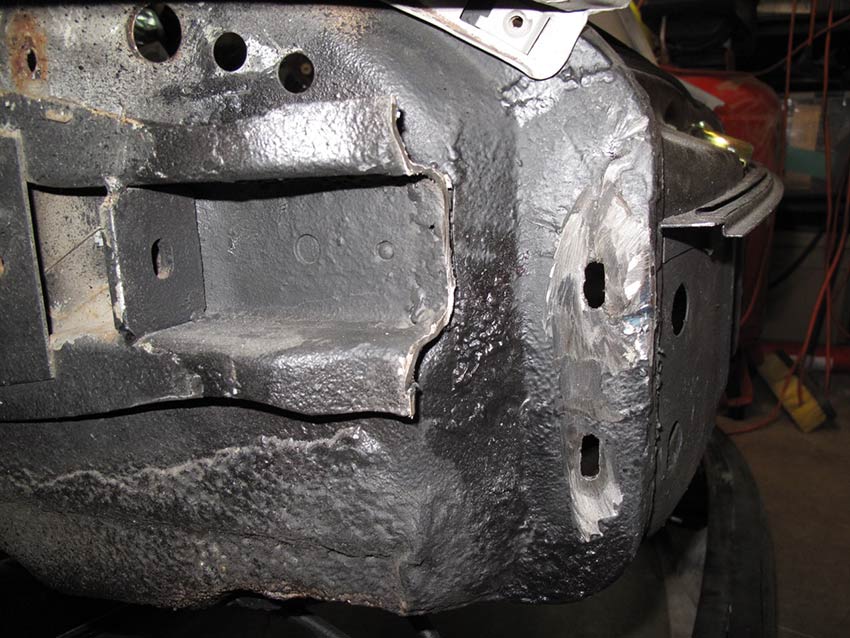

These '74 bumper mounts are in the way of the earlier bumper mounts and the long hood fenders.

Need to cut them back.

Earlier bumper mounts were just these little holes.

Bummper mounted on, now I can align the signal boxes.

Gasket helps align the signal boxes.

How the gasket fits in the front.

Used a compass to draw my cutting line.

Took quite a few discs, but the dremel makes a good cut.

Test fitting the signal box before cutting.

Getting closer, still some grinding to do to before welding.

Lots of grinding and fine fitting

All ready to tack it up

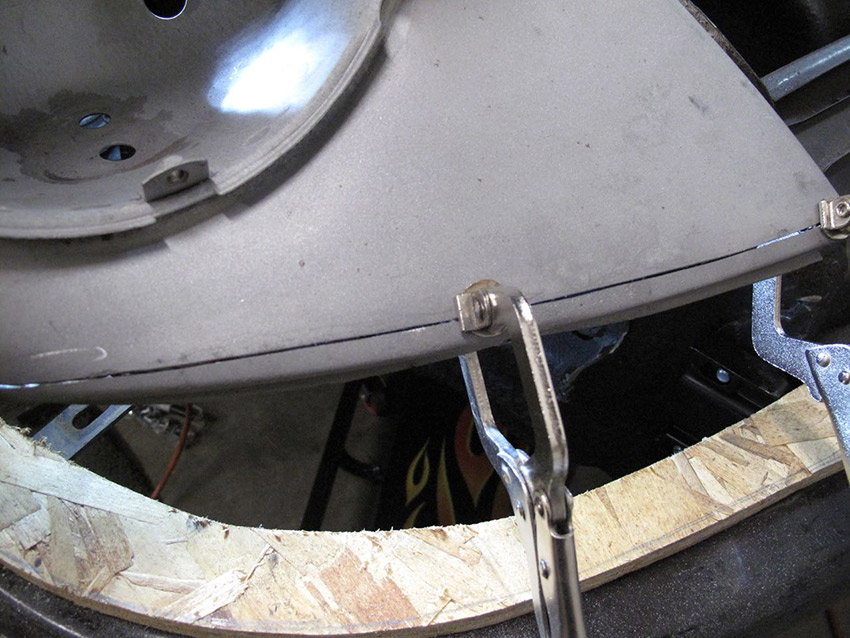

The wood is to simulate the gasket.

Now for the driver side

I ordered a whole piece to put in

Aligning the driver side with the gasket

Horn grill aligns with the hood and bumper

More of grinding, cutting and fitting today

but then it just fell into place, like that was where it was supposed to be.

Then I welded it in place.

Now to fill in the gaps and grind it smooth.

Both signal boxes are in. Yay!